Strain Gauges

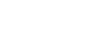

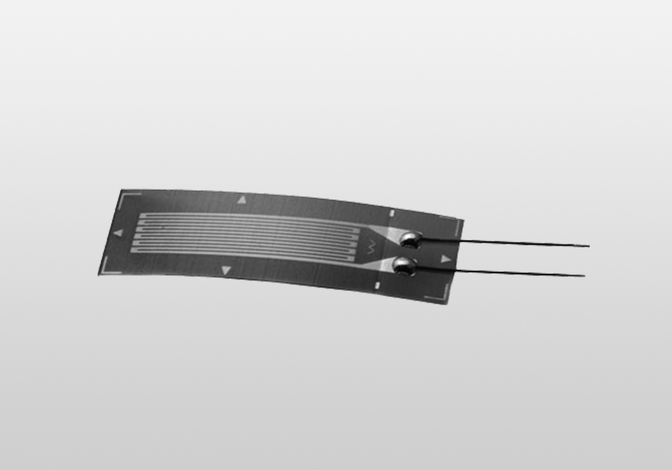

UNI-AXIAL / BI-AXIAL / ROSSETTE

Micro-Strain Level Measurements

Strain gauges form the fundamental measurement base for most of the experimental and on-site test setups. As well as direct strain measurements in full/half and quarter bridge configurations, many transducers used in Civil, Mechanical, Mining, Metallurgy, Materials & Geology Engineering are manufactured by bonding strain gauges on a metal setup. Load cells & many displacement/deformation gauges are manufactured in this way.

Strain gauges are used for stress/strain or load/deformation measurements in Structural Health Monitoring. Besides they are one of the indispensable components of academic research studies and laboratories.

UNIAXIAL / BIAXIAL / ROSETTE TYPE STRAIN GAUGES

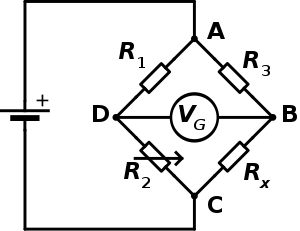

Wheatsone bridge is essential for direct strain gauge measurements. A wheatstone bridge involves 4 resistors, which among those at least one resistor is the strain gauge itself.

An excitation voltage is applied to one section of the Wheatstone bridge, and resistance change due to the deformation of gauge (where it is bonded) is acquired from the other section.

4 strain-gauges are needed for full-bridge configurations. On the other hand, different options of quarter-bridge & half-bridge configurations are also used for measuring axial or bending strains in different architectures depending on the material, geometry and the aim of the application.

TDG Engineers will guide you about the most effective configurations regarding your project.

1 strain gauge exists in quarter-bridge and 2 strain-gauges exist in half-bridge configurations. For these configurations, the Wheatstone bridge must be completed by external resistors. These external bridge-completion resistors should be in high accuracy and precision. TDG offers QCABLE product for completing the Wheatstone bridge in most-effective and noise-free way (for quarter & half-bridge). Furthermore, TDG Digitizers are fully compatible with strain-gauge measurements. TESTBOX2010-RACK, TESTBOX2010-FIELD and TESTBOX1001 include integrated "state-of-art" signal conditioner circuits for strain gauges.

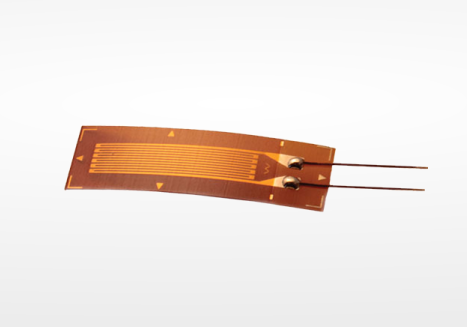

BONDING / COVERING / PROTECTION MATERIALS

For the correct measurement, the strain gauges must be strongly bonded to the surface of the material. The surface should be clean and smooth. The strain gauges should be covered with special materials against, dust, water and harsh weather conditions according to the interior or exterior applications. TDG offers a variety of bonding, covering, protection materials and connection terminals that best fit the application and the material (Concrete, Cement, Wood, Metal, Plastics, Composites, Porous).

- Best Prices for High Quality Strain Gauges

- Structural Health Monitoring / Stress-Strain, Load-Deformation

- Full / Half / Quarter Bridge Measurements

- 120 / 350 ohm Options

- Different Measurement Ranges (3-5-6-10-30 ... mm)

- Uniaxial, Biaaxial, Rossette Types

- Special Strain Gauges for Concrete, Cement, Wood, Metal, Plastics, Composites, Porous

- Low-Noise / Reliable Measurement with "state-of-art" Signal Conditioners & QCABLE

FIELDS OF APPLICATION

STRUCTURAL HEALTH MONITORING / STRAIN

INDUSTRIAL PLANTS / HISTORICAL STRUCTURES / BRIDGES & TUNNELS

STRESS / STRAIN - LOAD/DEFORMATION

ACADEMICAL RESEARCH / LABORATORIES

CIVIL ENGINEERING LABS

STRUCTURAL MECHANICS LABS

MATERIALS TESTING

AXIAL / BENDING / TORSIONAL STRAIN

CREEP / FATIGUE